|

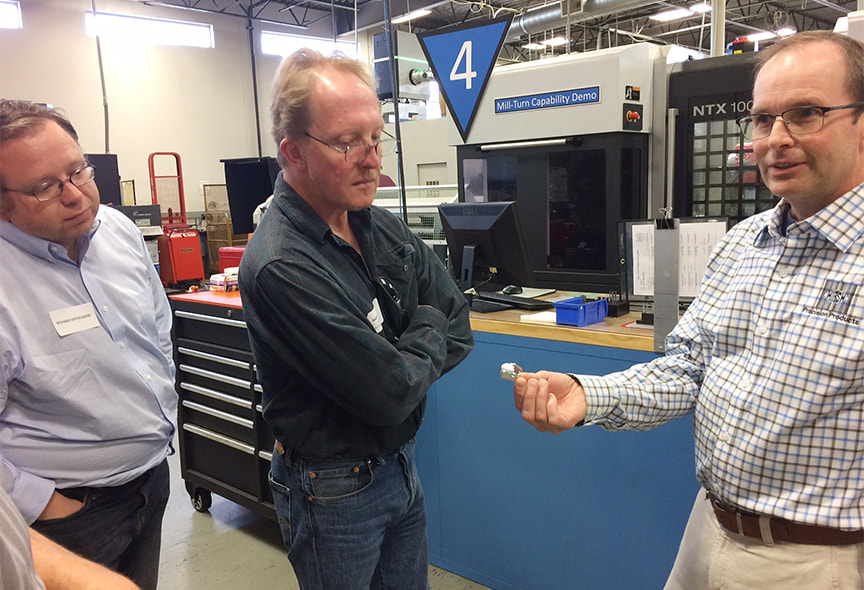

April Stay Connected Event... Hirsh Precision Products Tour & Happy Hour Our Stay Connected events happen once a month and is a chance for supply chain professionals to visit other facilities and learn from their methods. We get to meet leadership in these companies and then end with a networking happy hour. Join us for the education as well as the fun! Hirsh Precision designs, manufactures, and ensures the quality of precision-machined parts and assemblies. Our cutting edge equipment, technology, and processes attract the attention of multiple industries. We had another fantastic tour on the APICS NoCo circuit. Hirsh Precision Products hosted our group in Boulder at their state-of-the-art facilities. Our tour guides were Steve Hirsh (Founder/Director of Engineering), Mike Hirsh (President/CEO), Peter Doyle (COO) and Mark Cartwright (Production Scheduling & Customer Service Manager). All four were on hand to give us an introduction to the company before leading us through the production floor. Hirsh's work mix is two thirds medical, dealing predominantly with metal and plastic media. They currently run 2 shifts. Their eventual goal is to run 24 hours. The shop is divided into half milling, half lathing functions. In 21 machining centers, they average around 70 setups per week. The sweet spot in Hirsh Precision's business model is 25-500 items per order: larger than prototype quantities, and smaller than mass production. Our tour was divided into three groups, giving plenty of opportunity to ask questions during the busy afternoon shift. Team Hirsh discussed how increasing their automation doessn't reduce their number of headcount, just changes the type of jobs and work. Like many front range manufacturers, finding skilled labor is one of their biggest constraints. Their newest machine, the Fastems 8760, showed off a rack of 30 pallets and the ability to self-schedule. After 1.5 years in operation at Hirsh, the machine is at 70% capacity. They hope to push it closer to operating a full 8760 hours every year... hence, the name 8760 Fastems. The tour visited their Quality Assurance room, which featured a controlled climate and two CMMs (Coordinate Measuring Machines). Hirsh performs two inspections for each batch: First Article and in process, the latter of which triggers at a different frequency interval based on the part. Our group also gained a glimpse into Hirsh's internal scorecards and paperless shop floor management. Their PSA, or Plan/Schedule Adherence, takes a snapshot of each production line two hours into a shift to make sure everything is on track. This way adjustments may be made quickly and are easily caught. The final PSA formats were designed by the operators themselves to ensure the system was smart and agile. Maintenance for all of Hirsh's machines is also treated as a production item so necessary maintenance appears in the schedule and isn't overlooked. All of this factors into the ERP and proprietary shop floor software that ensures Hirsh can produce their high-quality product in a timely fashion. If you missed our tour of Hirsh this time around, be sure to check out their webpage at http://hirshprecisionproductsinc.com/. This was a packed tour with impressive machinery, expert guides, and excellent learning all around. Thank you to the team at Hirsh Precision Products for hosting an amazing tour! Questions We Asked Hirsh1. Does your facility employ Lean techniques and how hard was that for your company to implement?

Hirsh Precision is committed to continuous improvement and has implemented a variety of lean techniques. Our business consists of high mix, low volume production, so our production processes are based more around processes than dedicated product cells. Our initiatives include optimizing quality assurance inspections, completing non-value added activities in parallel with production, organizing the work environment based on 6S principles, and conducting regular kaizen events to identify and eliminate waste. 2. What is the difference between yours and the production systems run by your competitors? Our motto, “Quality Work Delivered on Time” guides how we invest in systems and business processes. We invest in the latest technology and often customize our machine tool investments to ensure they fit our customers’ needs. We have created proprietary software to manage our production processes, and we have a culture that encourages innovation, collaboration, and the pursuit of excellence. 3. How has your Lean management system bridged the gap between your organization and your customers? Our customers appreciate the price reductions we can offer as a result of our lean initiatives. In addition, our lean initiatives allow us to maintain consistent lead times and carry virtually no inventory. The strong relationships we have with our key customers allow us to share information that helps us better understand their needs and how we can become a supply chain partner. 4. Does your company have more of a focus on productivity or quality? Quality! 5. What value has your company leadership seen as a result of your lean management techniques? In the past several years, our investments in new technology and lean initiatives have allowed our team to learn new skills. A focus on efficiency makes our workplace more creative, fun, and engaging. In addition, we’ve been able to effectively push back on customer requests to stock inventory for which demand is uncertain. 6. What message would you want to give someone who might be considering lean management for the first time in their organization?

0 Comments

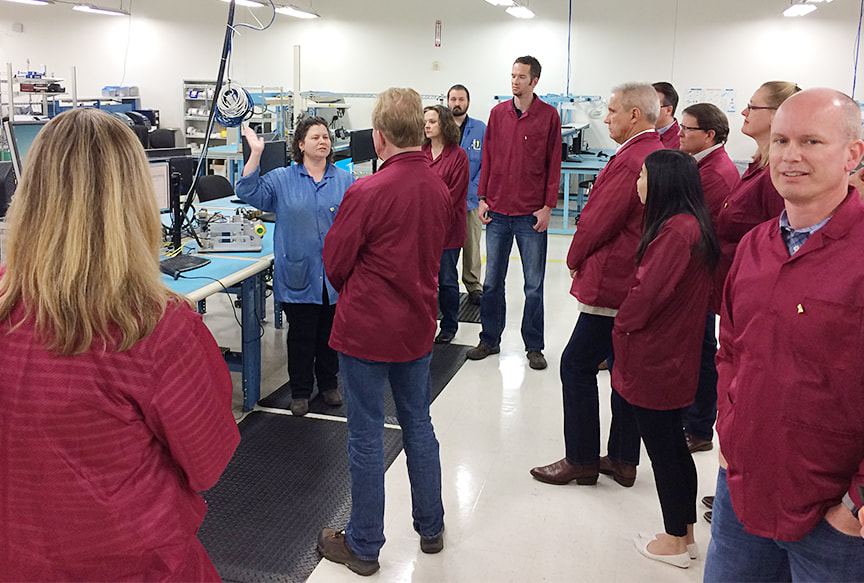

March Stay Connected Event... Vergent Products Tour & Happy Hour THE LEADING PROVIDER OF HIGH-DISCIPLINE PRODUCT DESIGN, MANUFACTURING AND SERVICE Vergent Products delivered an excellent tour with several highlights! The company started in 1996 in Loveland with three employees, one of whom was Diana Precht, our tour leader and Chief Communications Officer. What started as a design firm is now a multi-dimensional supply chain company with 140 employees. Vergent Products was founded on two core principles: exceptional client experience and the engagement of a diverse team of experts focused on continually elevating their clients’ success. QUICK FACTS

Our group started by donning smocks to prevent electrostatic discharge along the tour. We then enjoyed cookies from the host while hearing a pre-tour overview from our guides. Our first tour stop was a circuit board assembly station for Rachio water sprinkler systems. Multiple generations of the board were displayed, along with product improvements such as 14 screws in the 1st generation board, 0 in the second, and 2 in the current generation. Vergent's in-house designed work order system is paperless to prevent static discharge, involves visual cues to ensure people have the proper training for each step of assembly, and includes RFID scanning for all consumables and expirable inputs. This ensures that any testing issues are traced back to the exact units of input. One of the simplest yet most effective cues we learned about was pass/fail tags in two different sizes: this prevents shipment of units with any concerns because the visual cue is clearly interpreted. Speaking of which, nearly 100% of Vergent's circuit boards undergo an optical test to verify product functionality. At one station, we watched workers x-ray circuit board components to ensure solder points. Three quality control checkpoints ensure an extremely high rate of success in product testing. Our guides described upcoming improvements, including flow racking and assembly station reconfiguration to reduce time and movement. The current time for a Rachio unit assembly is 4.62 minutes of labor per unit and 3.5 minutes is the target goal once changes are in place. Toward the end, we passed the quality lab, an environmental test chamber, inventory storage (including vendor managed inventory) and talked about the various supply chain solutions Vergent has instituted over the years. Today, Vergent functions as an Amazon fulfillment center, handles order fulfillment for several other big box customers, houses a warranty and service center, and continues to offer design services to customers. They don't envision slowing down any time soon. Fifty percent of their business is PCBA assembly, and they continue to offer test engineering and strategies, as well as product development. Be sure to make it to the next tour if you missed this one! After our tour, we continue to the Sports Station for our networking happy hour. It was a fantastic event! |